If you've ever had to fly during the cold winter months, you've probably had to wait for the aircraft to be de-iced using chemicals in order to get rid of all the ice and snow that gets accumulated on the aircraft due to sub-zero temperatures, sometimes even leading to flight delays.

However, scientists from Germany have come up with a better alternative that makes planes ice and water repellent and this new technology minimizes the need for de-icers, perhaps even eliminating the need for them entirely.

How are planes kept ice-free?

Aircraft manufacturers and airlines currently employ different tactics to prevent ice from accumulating on the aircraft. The most common one being the fleet of tankers at airports that spray the aircraft with antifreeze chemicals. Apart from flight delays, this process consumes upwards of 600 litres of expensive antifreeze to de-freeze a large aircraft, and what's worse is that it's not even recyclable or environment-friendly.

Some aircraft deal with ice by using heating systems installed on the wings and other areas of the plane, or use setups that divert hot air from the aircraft's engines to the affected areas and melt away all the frost build-up. However, this consumes additional fuel, and fuel, as we all know, is also expensive.

New laser treatment – how does it work?

Researchers from Fraunhofer Institute for Material and Beam Technology IWS, aircraft manufacturer Airbus, and the Dresden University of Technology in Germany have teamed up to develop a better way to keep planes free of ice and snow.

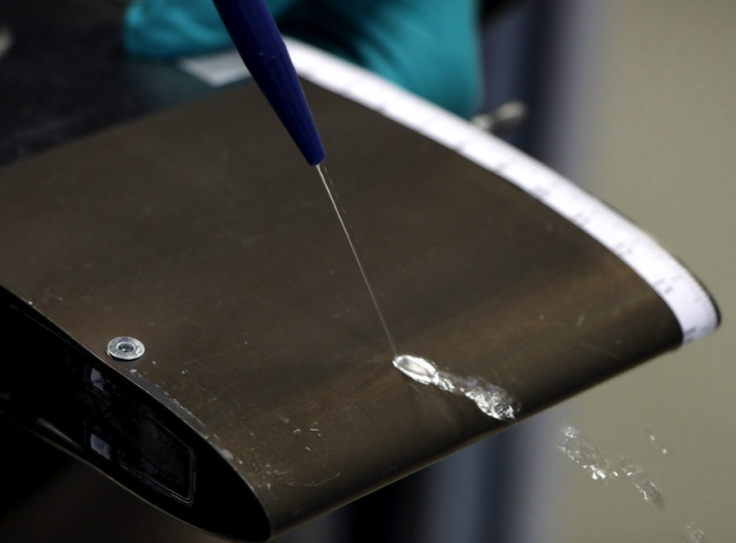

The new technology is called Direct Laser Interference Patterning (DLIP) and is essentially a laser treatment, where a laser is split into multiple beams that overlap each other to create complex etched patterns on a surface where the beams are focused.

This technique creates a three-dimensional structure, which can only be seen using a microscope and can turn an aeroplane's wing into a material with a surface area that ice or snow cannot hold onto. Because of this, after reaching a certain amount of thickness and weight, built up ice simply falls off the wings on its own.

This means that an aircraft can be cleared of any ice much faster without the use of chemicals, and aircraft manufacturers can use smaller heating systems that are just as effective, but with lower fuel consumption.

Where else can it be used?

DLIP technology is not restricted to aircraft. It can also be applied to everything from the blades of windmills, to the hulls of ships that navigate through icy waters. The laser treatment will serve as the best solution for frozen car windshields and windows that require you to painstakingly scrape off all the ice on a cold winter's morning.