Several pathogens can survive on different surfaces for varying amounts of time. Harmful bacteria are known to last on metal surfaces such as doorknobs and tables for long periods of time, and lethal viruses such as SARS-CoV-2 have been proven to survive for hours. What if the metal surfaces could kill these pathogens as soon as they come in contact with them? Engineers from Purdue University have managed to accomplish exactly that.

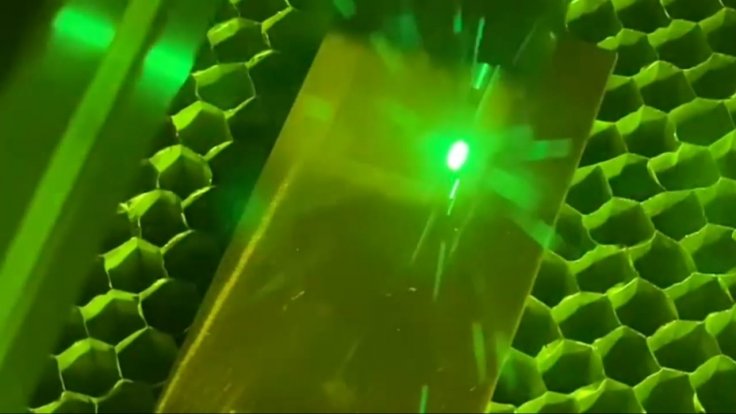

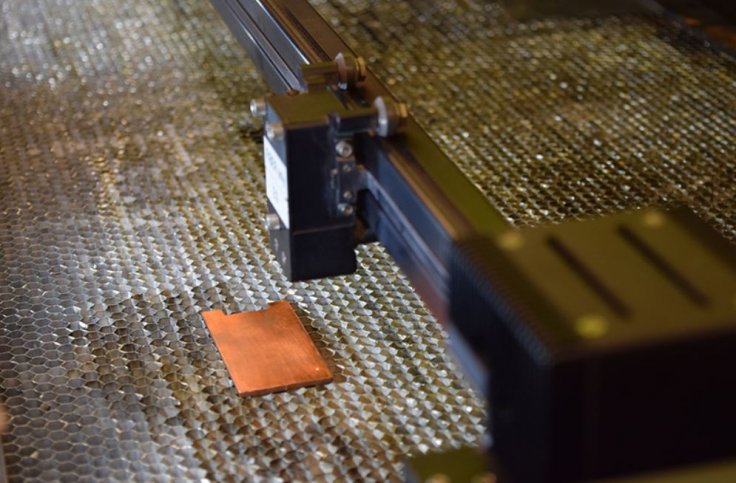

The researchers have developed a laser treatment technique that has the potential to infuse any metal surface with the ability to kill any bacteria. Using copper for the study, the researchers demonstrated the capacity of the laser-treated surface to destroy bacteria including the Methicillin-resistant Staphylococcus aureus (MRSA).

"We developed a one-step laser-texturing technique that effectively enhances the bacteria-killing properties of copper's surface," said Rahim Rahimi, lead author of the study. The technique, however, is not calibrated for viruses yet, which are smaller than bacteria.

Enhancing copper's antimicrobial properties

The antimicrobial characteristics of copper are not unheard of. However, the time taken for the metal to act against bacteria is long. Also, metals such as copper have very smooth surfaces. This diminishes the ability of metals to kill bacteria on contact. "Copper has been used as an antimicrobial material for centuries. But it typically takes hours for native copper surfaces to kill off bacteria," noted Rahimi.

This is where the new laser treatment technique comes into play. The method employs a laser for the carving of nanoscale patterns on the surface of the metal. These patterns result in the creation of jagged consistency that increases the surface area. This increases the chances of the bacteria hitting the surface of the metal and rupturing.

"We've created a robust process that selectively generates micron and nanoscale patterns directly onto the targeted surface without altering the bulk of the copper material," said Rahimi.

Testing the bacteria-killing ability of the surface

The treated surface of copper is exposed to the bacteria culture directly for 90 minutes under room temperature. During the course of this duration, the amount of bacteria on the surface is calculated at regular intervals.

"We found that the surface that is laser-treated has much more rapid killing of bacteria than the one without laser treatment," explained Vidhya Selvamani, co-author of the study, in an accompanying video.

Extending the technology to other metals

Following the publishing of the current study, Rahimi and his team have begun testing the technique on other metal and polymer surfaces that are utilized to decrease the risk of bacterial growth. The technique can also be used for the formulation of biofilms on devices such as orthopaedic implants.

According to Rahimi, providing implants with antimicrobial surfaces could eliminate the risk of infections and counter antimicrobial resistance. This is because the need for additional antibiotics to kill the bacteria on the surface of the implants will be reduced or negated. Other metallic alloys known to have antimicrobial properties can also be enhanced using this technology.

Dual advantage

Earlier researches have involved the use of different types of nanomaterial coatings in order to magnify antimicrobial properties of metallic surfaces. However, the tendency to leach away exists in these coatings, thereby making them environmentally unviable due to their potential toxicity.

Texturing of metal surfaces using a laser also has a twofold effect. While direct contact with the surface improves significantly, the technique also improves the surface's hydrophilic properties. (i.e) its ability to bond well with fluids. This can be immensely helpful in the case of orthopaedic implants as such a surface will improve the integration of the implants with bone cells by attaching itself better. This effect was already observed by the researchers in fibroblast cells

Rahimi's team believes that the scalability and simplicity of the technique can be easily adapted into medical devices manufacturing processes already in existence.