When you hear "3D printing," you might first think of custom medical implants or intricate prosthetics. While additive manufacturing (AM) has indeed revolutionized healthcare, its impact stretches far beyond the operating room, quietly transforming industries from electronics to aerospace, and even the food we eat. This technology is ushering in an era of unprecedented customization, complex designs, and remarkable efficiency, fundamentally changing how products are made globally. At the heart of this widespread revolution is the relentless pursuit of precision, a field where Dr. Yumeng Wu, an Applied Scientist with a Ph.D. from Purdue University, plays a pivotal role. His work on advanced control systems for inkjet 3D printing is not just about medical breakthroughs; it's about enabling the high-quality, reliable manufacturing that industries worldwide now demand.

Achieving consistent, perfect shapes in 3D printing, especially at the microscopic scales often required for advanced applications, presents significant challenges. Variables like ink viscosity, droplet size, and material curing can easily lead to imperfections. Dr. Wu's breakthrough lies in developing sophisticated yet efficient control methods to overcome these hurdles. His doctoral research introduced a novel model that precisely predicts how each layer of printed material will stack up, ensuring geometric integrity. Beyond theoretical models, he developed real-time control strategies, adapting image processing techniques and formulating advanced model predictive control to dynamically adjust printing parameters on the fly. This integrated system for precision control is what elevates inkjet 3D printing from a prototyping tool to a dependable, high-precision manufacturing method, essential for meeting stringent quality and safety standards across diverse sectors.

This newfound precision is reshaping the electronics and optics sectors. Imagine printing flexible electronic circuits directly onto an aircraft wing or a car door, eliminating the need for separate components and assembly. This capability enables miniaturization and integrated functionality previously impossible, leading to lighter, more compact, and robust systems. Beyond performance, electronics 3D printing offers significant environmental advantages by drastically reducing waste and power consumption compared to traditional methods, and it supports the strategic goal of bringing manufacturing back to the United States.

In aerospace and automotive, additive manufacturing is driving innovation through lightweighting and performance optimization. It enables the production of complex internal structures, like intricate trusses, that significantly reduce weight while maintaining or enhancing strength, directly improving fuel efficiency and overall performance. Beyond end-use parts, 3D printing is invaluable for rapid prototyping, creating specialized tools on-demand, and enhancing Maintenance & Repair Operations (MRO) by allowing local printing of spare parts, reducing downtime and inventory costs across heavy industries.

The impact extends to consumer goods, food, and construction, bringing unprecedented personalization and addressing societal challenges. Consumers can now access custom-fit eyewear and shoes, tailored precisely to their needs and preferences. In the food industry, 3D printing allows for customized appearance, texture, and flavor, with the potential for on-demand production of personalized meals, even for specific dietary needs like those of astronauts. For construction, 3D concrete printing is improving the efficiency of building components and is expected to be widely adopted for residential, commercial, and emergency housing by 2030, offering faster and more cost-effective solutions to global housing challenges.

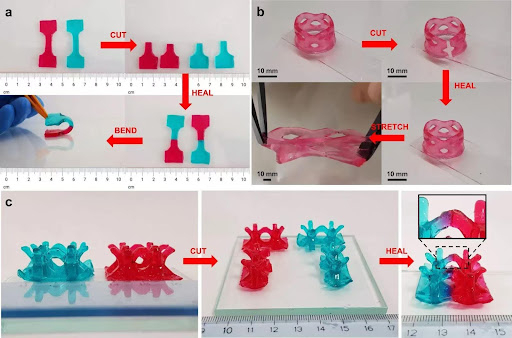

Even the energy and advanced materials sectors are benefiting. Additive manufacturing enables the creation of complex geometries for components like electrodes and bipolar plates, enhancing the performance of batteries and supercapacitors through increased surface area and reduced losses. This technology also contributes to reducing the carbon footprint and increasing material efficiency, aligning with global sustainability goals. The ability to precisely engineer materials like hydrogels, with their customizable properties, further unlocks new possibilities for functional materials in sensing, food, and cosmetics, beyond their well-known biomedical uses.

The consistent emphasis on "patient-specific" and "customized" solutions, enabled by Dr. Wu's precision control, highlights a fundamental shift from mass production to "mass customization" across all these industries. His work makes it economically viable and scalable to produce tailored products, ensuring individual needs can be met with unprecedented efficiency and affordability. This represents a profound and transformative impact, making advanced, individualized solutions accessible on a broader scale.

Dr. Yumeng Wu's groundbreaking contributions have earned him significant recognition within the global scientific and engineering communities. His extensive publication record, often co-authored with his distinguished advisor, George T.-C. Chiu, showcases his consistent contributions to the field, including his Ph.D. dissertation on "Height Profile Modeling and Control of Inkjet 3D Printing" and key papers on advanced control strategies. Beyond academic publications, Dr. Wu's impact is evident in his role as an inventor on multiple patents, including those with a major corporation like Xerox, which demonstrate the practical application and commercial potential of his research. These patents are concrete proof that his innovations have moved beyond theoretical concepts to create tangible, protectable technologies recognized and adopted by industry.

Looking ahead, the additive manufacturing industry is projected to be valued above $40 billion by 2030, with widespread adoption across the broader manufacturing sector, even becoming competitive with injection molding for large batch sizes. This growth is fueled by increasing automation, integration with Industry 4.0 technologies like AI and IoT, and continuous innovation in materials, including multi-material printing. Additive manufacturing is also poised to play a crucial role in promoting circularity and sustainability by enabling localized production, reducing waste, and minimizing energy consumption, fundamentally changing supply chains and environmental impact.

Dr. Yumeng Wu's pioneering work in advanced inkjet 3D printing control is not just an academic pursuit; it's actively shaping the future of manufacturing. By enabling unprecedented levels of precision, speed, and customization, his research is directly contributing to a new era where products are not only more effective and accessible but also precisely tailored to unique needs across every industry. His dedication to solving complex engineering challenges firmly positions him as a visionary leader, critical to unlocking the full, transformative potential of 3D printing for a more efficient, sustainable, and personalized future worldwide.(By:Carl Williams)