Researchers from the Wyss Institute at Harvard University and MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed artificial muscles for robots which could allow them to lift weight up to 1,000 times their own weight using air and water pressure.

The vacuum powered muscles are safer than most of the other artificial muscles as it has lower risks of rupture, failure, and damage. They have been designed to be human-centric and could be used in closer-flitting robots in the human body including the artificial limbs.

Researchers around the world had been experimenting with different materials and designs to allow once rigid, jerky machines to bend, flex, and mimic living organisms. Softer materials which allowed more flexibility and dexterity had lesser strength whereas stronger materials didn't match the requirement.

According to Daniela Rus of MIT, "We were very surprised by how strong the actuators [aka, "muscles"] were. We expected they'd have a higher maximum functional weight than ordinary soft robots, but we didn't expect a thousand-fold increase. It's like giving these robots superpowers."

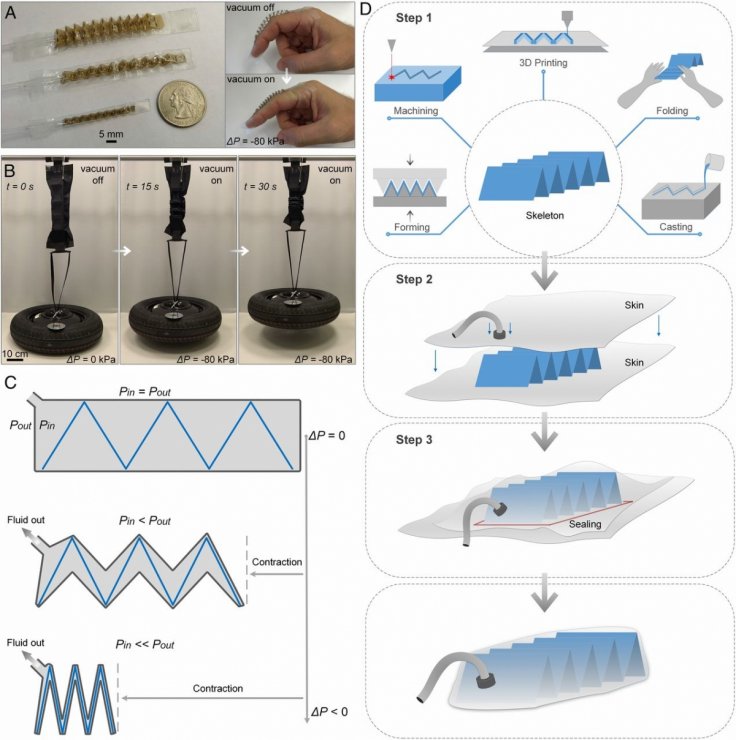

The paper published in the Proceedings of the National Academy of Sciences (PNAS), each muscle has been built with inner "skeleton" of metal coils or plastic sheets folded in particular patterns surrounded by air or fluids. Plastic or textile bag serves as its skin. Vacuum pressure pumped into the muscle creates pressure which regulates its movement as the skin contracts onto the skeleton. The muscle function does not require any external power source or human interference and is completely dependent on the composition and shape of the skeleton.

Researchers said the folding of these programmed muscle's skeleton could define the entire motion of the structure. A researcher could understand the motion prior to it without the help of control systems. The new technology could improve the muscles and keep it compact and simple. It could be used in mobile or body- mounted systems that cannot accommodate large or heavy machinery.

The researchers constructed dozens of muscles using materials including metal springs, packaging foam and plastic sheets and experimented it in different shapes. They succeeded to develop muscles which contracted up to 10% of its original size.

The newly constructed artificial muscles could generate six times more force per unit area than the mammalian skeletal muscles. These incredibly lightweight muscles could be constructed within ten minutes using materials costing less than one dollar.

The artificial muscles could be constructed in wide size ranges which enhance its benefits to fields like miniature surgical devices, wearable robotic exoskeletons, transformable architecture, and deep- sea manipulators for research or construction and for space explorations. Scientists have also developed the muscle from water-soluble polymer PVA, which could be used in ingestible robots that would move to target locations in the body to release specialized drugs.